I was recently asked by the NYC Department of Sanitation to keynote at their SOAR Strategic Partnership Breakfast which was also highlighting International Women’s Day. It was a great opportunity to enlighten urban sanitation folks about biochar. With a few edits, here is my talk (warning – longer than most of my blog posts but hopefully it will be of interest).

It’s been far too long since I roamed the streets of NYC as one who called it home, but the invitation to return and hear about what is going on in the world of waste, or as I prefer to call it, unloved organics, was more than a little appealing. When I last lived here my career was about as far away from reimaging or repurposing organics as it is possible to get. I did a mid-life career 180 after going back to complete a Masters in Sustainability about a decade ago. It was during that time that I read about a little something called biochar which changed the entire course of my life! At the time I had no idea how few people had ever heard of it, nor did I think that 10 years later, roughly 98% of anyone I’ve ever talked to about biochar would respond with ‘bio-what’. But over the last year or so, things have really started to change rapidly on so many different fronts within the industry, that I am convinced the future for biochar is bright. So if you had never heard of biochar before getting your invitation to this event, know that you are in the vast majority, but please allow me to enlighten you just a bit about this exciting and diverse material and the process by which it is made.

Biochar is a fancy new name

for a material born from an ancient indigenous waste management practice – most

likely devised by women in my humble opinion – since it centered around cooking.

The process seems astonishingly simple in retrospect yet had profoundly positive

and long-lasting impacts. As you might

imagine cooking in fire pits produces prodigious amounts of hot coals. It appears

that human urine and probably other ‘leftovers’, were dumped on top of the

burning coals in an effort to both reduce odors from urine and feces and to thoroughly

quench the fires. Whether by accident or design this combination eventually converted

crappy soils – that’s not the technical term but I grew up on a farm and that

is how you usually hear low fertility soils described – into highly productive

soils capable of feeding a population far greater than had been previously

imagined. Fast forward a few millenia and those same soils are still up to 4x

more fertile than surrounding soils in the Amazon which were untouched by human

hands. In fact, those same soils are being dug up and sold to boost soil

fertility elsewhere.

Late last century these highly

fertile soils were re-discovered and piqued the interest of soil scientists and

archeologists. More recently the biochar

industry has garned interest from a much more diverse flock such as waste

managers, urban planners, the construction industry and climate change

scientists and activists. The reason for

this diverse interest is that the production and use of biochar brings with it

a range of benefits. Those of interest to this gathering include:

- Volume reduction – depending on the temperatures used and the organic material volume can be reduced by 70 – 95%!

- Speed – compared to other organic management practices, the use of high heat and low oxygen, what we refer to in the industry as thermo-chemical conversion or TCC can be done in minutes or hours versus weeks. Thermochemical conversion includes technologies such as pyrolysis and gasification, but it should not be confused with incineration. Think of it more like baking; you put something in the oven, close the door and crank up the heat. If you are anything like me, sometimes you get something that is not at all appetizing, but it is my favorite color – black! This unappealing taste may be why soil microbes and decomposers don’t like to consume it allowing carbon to persists in soils for millennia.

- Odor & pathogen control – TCC can also significantly reduce and in many cases eliminate odors and pathogens both directly and indirectly – meaning when added to landfills, compost piles or manure slurries, it can bind or hug toxins to prevent them from leaching and do the same with ammonia which causes the all too-familiar smell of ‘eau de landfill’.

- Scalability – technologies for converting organics to biochar range from backyard kilns capable of carbonizing tree debris, to community scale, to multi-million dollar production facilities.

- Renewable energy – some TCC technologies can harvest the heat generated from baking the organic matter. This heat can either be used for drying wetter material or can be used for other heating needs. Other equipment produces syngas which can be used to generate electricity while still others produce bio-oil which can be refined to be used as a fuel.

- And finally, there is the carbon impact. Organics sent to landfills or even to compost facilities can emit significant GHGs. While carbonizing organics with high heat and low oxygen does produce some GHGs, when managed properly TCC is considered a negative emission technology (or NET), meaning the overall impact is that more carbon will be prevented from returning to the atmosphere than is emitted. Think of it as carbon interruptus. This is something the IPCC and others have said is critical to avoiding climate chaos.

We are seeing more requirements to reduce and neutralize emissions at least in NY, if not at a national level. Given that, shifting from a carbon belching process to a carbon banking one, may be well worth considering. And though the carbon markets in the US don’t yet recognize biochar production and use as a product category, that is one of the areas that is starting to change very quickly. I predict we will start to see increasing revenues focused on carbon removal (e.g. NETs) versus carbon reductions (i.e. from renewable energy generation). Biochar is likely to be a key component of carbon removal markets.

A growing number of closed

loop biochar production scenarios are sprouting up across the globe. Here are

just a smattering.

- One of the oldest can be found in Austria where a compost company, Sonnenerde, began accepting paper mill waste and turning it into biochar which was then blended with different compost recipes. Adding biochar to compost can not only reduce odors and pathogens as I mentioned, but it can boost temperatures, speed up the processing time, hold on to more nutrients, serve as a bulking agent and provide longer lasting carbon to the soil.

- One of the most talked about models hails from Stockholm where the city converts green waste from residents and city Parks into heat that is fed into a district heating system and biochar. Their first demo plant was launched as a way to reduce the amount of biochar they imported from other countries which they had been using to improve urban tree survival. An unanticipated benefit they discovered as they began to use more and more structured soil made up of gravel, compost & biochar is that the amount of rainwater that could be stored during storms increased significantly while the amount of toxins from roads and roofs that had to be dealt with at the waste water treatment plant decreased. These toxins were bound in the biochar. City officials took notice and now this model is being replicated not only across Sweden and Europe, but here in the US as well where I believe Minneapolis is the first large city to be planning a pyrolysis plant.

- More recently an Australian company, Rainbow Bee Eater, located a carbonizer in an enormous 2 acre greenhouse to provide renewable energy. The fuel for the carbonizer is wood supplied by a local composter who provides it for free in exchange for taking the biochar produced from the machine which is added back to their compost.

- Closer to home is an enormous gasification plant being built in New Jersey by Aries Clean Energy. They plan to convert 440 tons per day of sewage sludge into 22 tons per day of char. A long-term offtake agreement has been signed with a local cement company that will be using it as a filler instead of fly-ash, a by-product from coal fired electricity generation plants. In the past decade alone roughly half of the coal generating capacity has been shuttered so cement manufacturers are on the look-out for new alternatives.

- East of here, out on Long Island, 2 projects are being investigated aimed at carbonizing mountains of wood chips which are leaching heavy metals into the groundwater. The goal for at least some of the biochar to be produced is to use it in bio-filters across the island to reduce the amount of nutrients, phosphorus mostly, leaching from hundreds of thousands of septic systems into local water bodies causing massive algae blooms and die off of various native aquatic species.

- And in Western NY where I live Cornell University in collaboration with NYSERDA is looking at siting the first pyrolysis plant on a dairy farm to deal with excess manure. Amongst other end uses for dairy manure biochar, we will be looking to use it to filter the wastewater from dairy production or possibly the effluents from nearby food processing companies such as yogurt or tofu manufacturing. Using biochar in this way harvests the nutrients and allows them to be cycled back into the soil for use by plants. We dubbed this kind of beneficial carbon cascade the ‘filtration to fertilizer’ approach

- I’ve also been working with the Rochester Institute of Technology for the past several years on converting different types of food waste into biochar. Biochar made from mixed food waste may have a lot of salt or chlorine, so using it in soils may not be the best solution. Instead we’ve been looking at using it in different types of composites. I have a prototype here which is a non-plastic, compostable tray made using 20% coffee waste biochar. One could call it biodegradable but I don’t love the term biodegradable due to the negative connotations of the word ‘degrade’. Instead I prefer bioUPgradable, since biochar-based products will sequester carbon and not produce GHG emissions whether you compost it or toss it in the landfill.

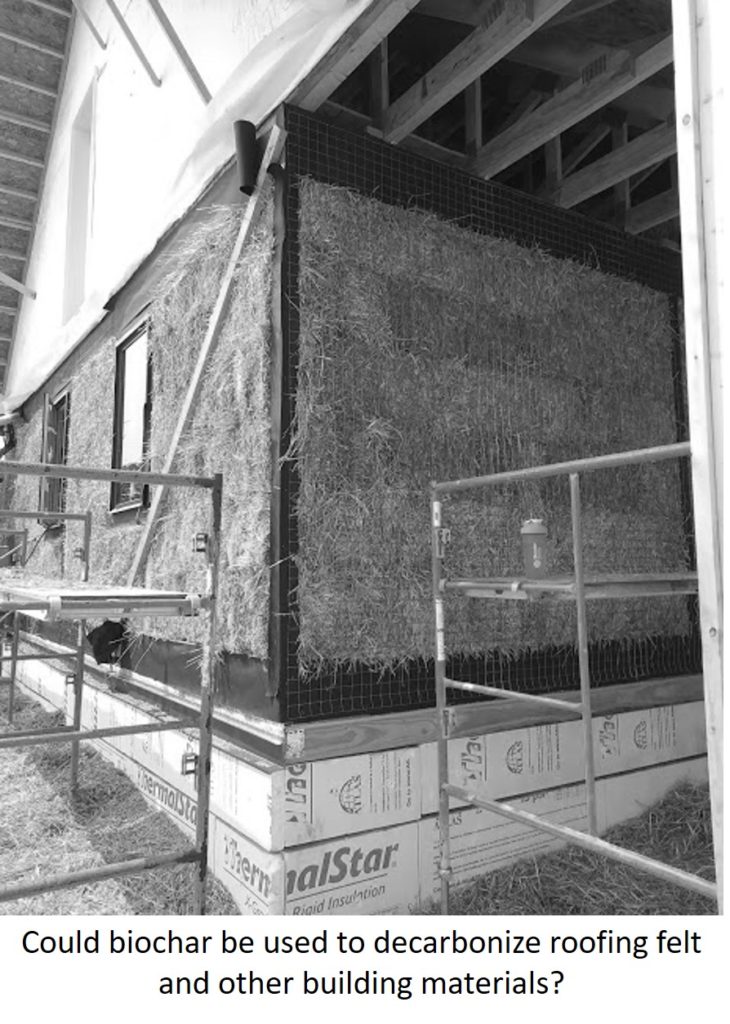

Low or variable quality

biochar from mixed food waste or sewage sludge is also being tested in asphalt

while higher quality and more consistent biochar is starting to be used in

building materials such as flooring, composite lumber, and exterior siding.

This will hopefully encourage the construction industry to build vast new above-ground

carbon sinks.

SUPPORT NY LEGISLATIVE GOALS

There are a growing number of ways biochar can help New York achieve some of the ambitious legislation that has been passed in the past year or so. The Organics Mandate prohibiting large scale food waste from being sent to landfills is one example. Providing additional ways to deal with food waste such as TCC, could support broader adoption. Co-locating pyrolysis with composting operations or anaerobic digesters may make a lot of sense.

I’ve mentioned the boost to

compost that adding biochar can make but there are also synergies with

anaerobic digestion as well. One issue some AD operators have is managing the excess

fiber or digestate. Digestate can be

used as a feedstock for biochar and help reduce volumes. The resulting digestate biochar can be fed

into the digester as a carbon source. Research has shown that this can improve

the quantity and quality of methane produced making the economics of operating

a biogas plant more attractive. Biochar also seems to provide a kind of buffer

which helps smooths out production ups and downs which occur when the substrate

mix is changed. Adding biochar can also reduce the amount of hydrogen sulfide

produced which can be harsh on equipment, reducing its operating life.

Biochar can help New York achieve

the aggressive yet vital goals that were set forth last year in the Climate Leadership

and Community Protection Act. That legislation

committed NY to a goal of 85% reduction by 2050 with all sectors being net zero

emissions by then as well. To reach net zero, those that cannot completely eliminate

all emissions must offset any remaining emissions through projects that

permanently remove GHG from the atmosphere. What is new and I think important that

NY has done with this legislation is that they will not allow renewable energy to

be used as an offset as that is already baked into the reduction goals. There are not that many ways to permanently

remove GHGs from the atmosphere. Trees can do an excellent job pulling CO2 from

the atmosphere, but as we’ve seen out West and Down Under, those trees are

increasingly at risk of going up in smoke and giving back all the CO2 they

absorbed during their lifetime.

According to the IPCC biochar is one of only 6 technologies touted as being able to make a material difference in rebalancing atmospheric carbon levels. Half of the other suggested technologies have yet to be proven economical viable or environmentally benign. In comparison biochar production and use is safe, scalable and shovel ready. It provides multiple benefits above and beyond the ability to help mitigate and adapt to climate change as I’ve already described.

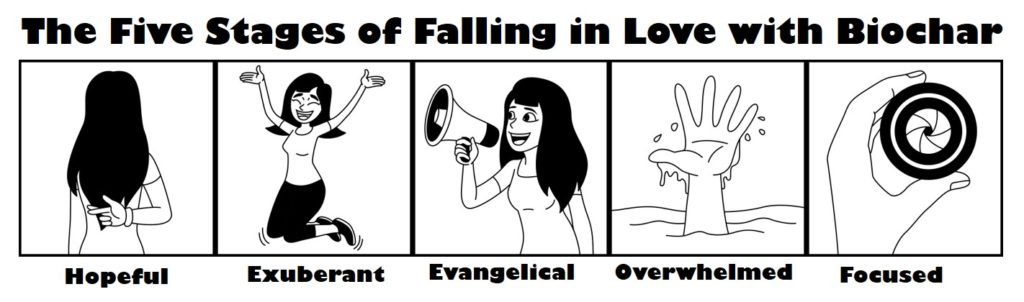

So with all this good news,

why haven’t more people heard of biochar and why haven’t more communities adopted

this kind of waste management approach? That is a question I get asked A LOT. In

fact, I ask myself this question all the time.

A few years ago, the lack of

biochar adoption could have been blamed on the lack of sufficient time-tested equipment

or, importantly, local technical support available to make a good quality,

consistent biochar. That has begun to change.

One of the reasons I believe

biochar has so far struggled is that the primary market targeted over the past

decade has been agriculture. In the early days of any new industry when

production is low and prices are high, going after a market that is already

very low margin and high risk is probably not the best first step. Until or

unless farmers start getting paid to build soil carbon their focus must, of necessity,

be on the lowest cost means of production and right now biochar is too

expensive for many annual crops when you compare it to cheap chemical

fertilizers

Over the past few years though the industry has begun to expand their market focus beyond soil applications. Nowadays we are looking at less seasonal and more repeatable markets such as filtration where it can compete cost effectively against activated carbon, or in plastics and other composites where it can displace carbon black, a high cost fossil fuel product used in everything from back plastic bags to tires. It’s even finding its way into batteries. Those higher value markets will enable production to scale which will enable prices to fall which will hopefully then make it more economically feasible for most farmers to use it.

As with every young industry, we have seen companies enter and fold, we have had our fair share of snake oil salesmen and those hoping to quickly cash in on a perceived gold-rush – mind you many of those are the ones that have already departed, thankfully. Right now we are seeing an unprecedented level of interest from impact investors, carbon brokers, communities choking on waste, foresters desperate to remove excess biomass and of course many who are beginning to panic when it comes to climate change.

We are thrilled at all the new

interest but those of us that have been in the industry for years understand

and want to make sure that others understand that biochar is not a silver

bullet nor is it like the Field of Dreams where you can expect to have

unlimited demand once you start making biochar. To make the economics work and

to maximize the carbon impact, it is critical to create biochar production

scenarios that embrace the circular economy, that utilize all possible

co-products including heat, and to build local markets instead of shipping

biochar half way around the world – something which is happening far too frequently.

Waste managers are uniquely poised to help build this industry but my advice

would be to partner with someone that knows biochar well before you dive it.

There are as many different kinds of biochar as there are different kinds of

biomass; more really since different production parameters generate different qualities

in biochar. Each of these types of biochar may be good for different markets

and therefore the expected price for it will differ.

With that said, I welcome each

and everyone of you to learn more about biochar. We need to scale this industry

quickly and efficiently.

If you are interested in

learning more about biochar, the Rochester Institute of Technology will be

hosting a free one-day thermo-chemical conversion and biochar workshop on April

20th up in Rochester. All are invited though registration is limited

and required.

I also need to give a shameless

plug for a book I co-authored last year called BURN: Using Fire to Cool the Earth. In this book we explore many of the markets I’ve

mentioned today and more.

Many thanks for listening (well reading in this case!) and Charpe Diem!