Using the word fertilizer to describe man-made chemicals that are spread or sprayed on soils is perhaps the most unintended oxymoronic word choice ever, except for maybe plasticulture which I lamented long ago. While chemical fertilizers may help individual farmers realize short term crop yield increases, the long-term impacts to soil, air and water are overwhelmingly negative for those self-same farmers as well as many downstream flora, fauna and human folk.

Consider recent news that fertilizer production is responsible for belching out 100x more methane into the atmosphere than had been previously acknowledged. As CH4 is hugely more worrisome than CO2 from a warming perspective, this is a big deal. Or ponder perhaps the plight of polluted pools of water, starved of oxygen caused by leached fertilizer and manure. Fisher-folk around the world are now facing long-term unemployment because fertilizers have created dead zones, some as big as New Hampshire.

Chemical fertilizers are more akin to steroids which definitely boost short term performance but come with numerous unintended consequences. Perhaps a better name for them might be Ferticides when you consider their overall impact?

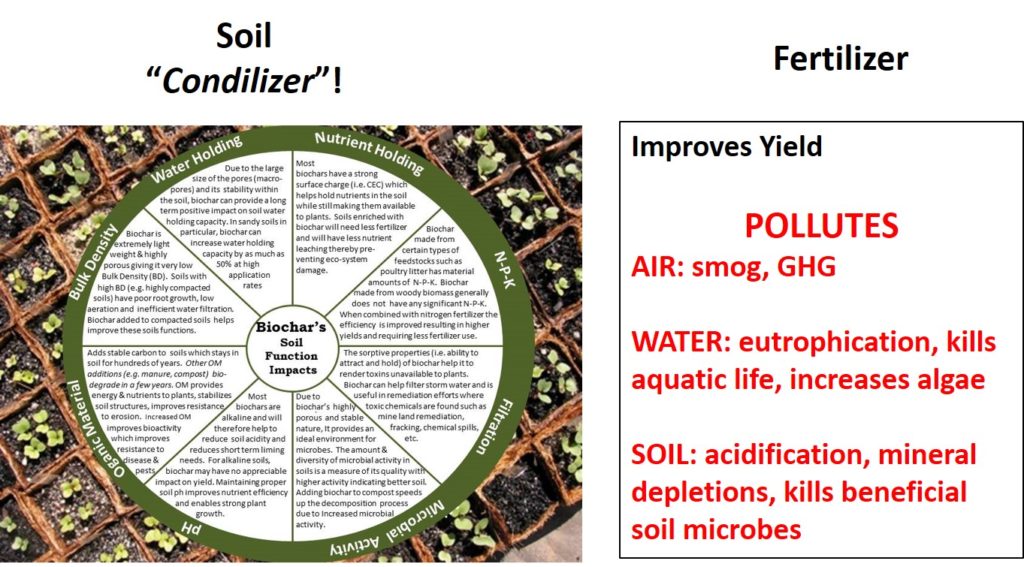

It is not uncommon for folks to talk about biochar as a fertilizer. However given all the negatives that come with fertilizers, perhaps we should refrain from equating it with these manmade soil steroids? Here are three reasons why biochar should be considered as something different from and, if I may suggest, better than fertilizer:

- Nutrient content: Many types of biochar do not in and of themselves contain nutrients that plants need. This is especially true of biochar made from woody materials. Many early research studies failed to recognize this, so yields were negatively impacted in the short term (which is unfortunately the length of time under study!) while biochar soaked up surrounding nutrients which were often released back to plants more slowly later on. While those early studies continue to be referenced as a reason not to use biochar, the biochar industry has long since learned that biochar should be combined with nutrients before soil application. Fortunately, there are many, many ways to do that with a wide variety of organic materials.

- Short-term vs long-term focus: fertilizer must be applied annually or even more frequently as it is subject to losses in the form of leaching, denitrification and volatilization. Biochar, on the other hand, is much longer lasting. Although flooding can move biochar from its original application location, it is still likely to persist wherever it ends up (unless it ends up in a fire!). While it is probably better to add biochar slowly so as not to shock the soil ecology, application of biochar is not needed indefinitely. After a few years of repeated application, soil organic matter content should reach levels that will promote long term fertility without the need for additional biochar.

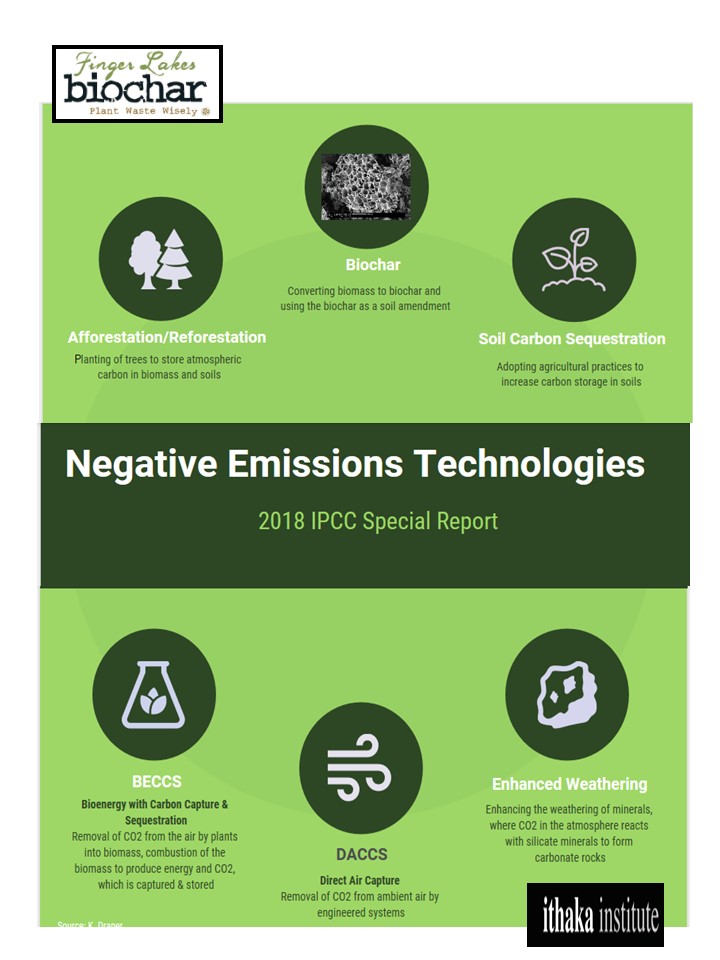

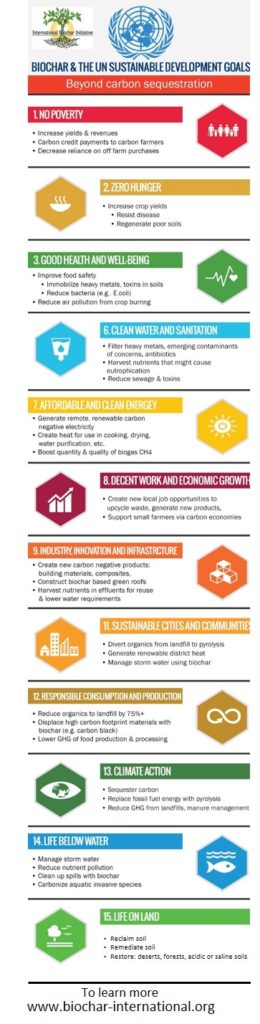

- Singular focus vs multi-beneficial: Fertilizer companies emphasize the need for increased food production yet minimize the systemic negative impacts it has on the planet. This plays into our fears of food shortages, while downplaying the overwhelming negative externalities, a ploy also used by Big Oil, Big Pharma and others. Biochar combined with appropriate nutrients can provide a wide variety of benefits not only to soils, but in displacing fossil fuel derived energy, boosting photosynthesis and rebalancing atmospheric carbon.

While there are additional reasons to refrain from referring to biochar as a fertilizer, these three provide fairly compelling reasons to find or invent some new vocabulary. Condilizer anyone?