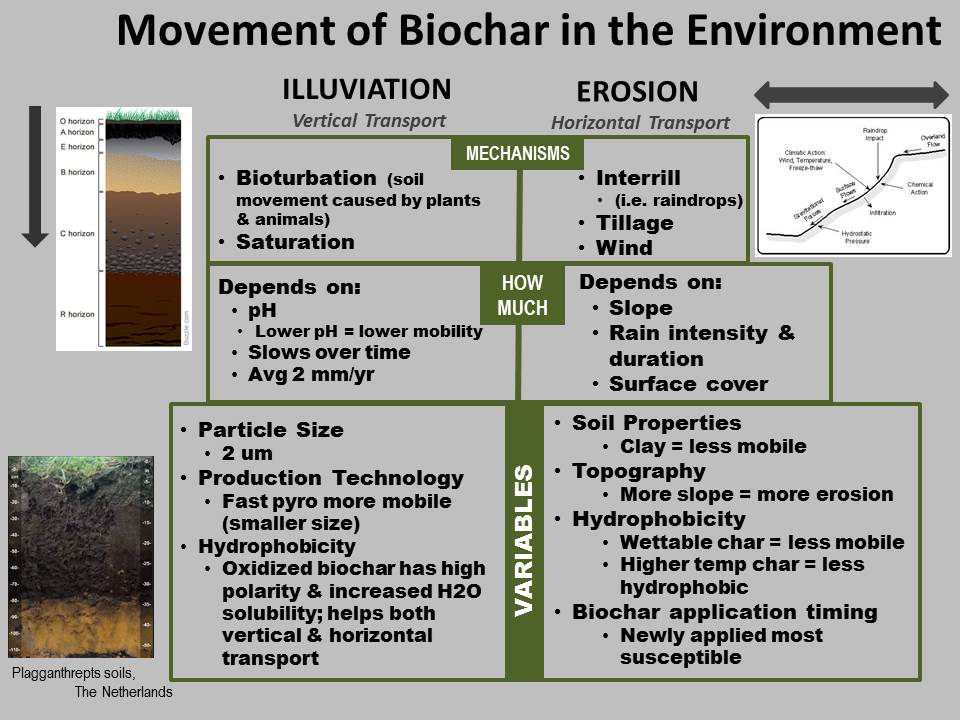

Next up on my reading list from the biochar bible, is Chapter 11 “Movement of Biochar in the Environment”. Rather unsurprisingly something light and fluffy such as biochar is fairly mobile. It can move both vertically down into the soil profile and horizontally across the landscape and into water bodies. Lots of different forces cause this movement as can be seen from my one page overview above.

It is possible, in some scenarios, say for example freshly top-dressed, hydrophobic char applied on steep slopes with no soil cover, that quite a lot of char could be eroded away during the next big rain (similar to how freshly applied Nitrogen gets leached away). The final resting place of that biochar varies largely depending on topography, but there is a good chance that it could still sequester carbon whether it is in the soil or in a body of water. If char simply moves across land, it may fractionate and some tiny particles may volatilize, but much of the char will simply be moved from one spot to another – much to a farmers chagrin. If it lands up in water, the carbon may still remain as carbon, but as with so many things related to biochar ‘it depends’! From what I can tell after reading this chapter, a lot more research is needed to really assess carbon stability in real-world vertical and lateral transportation scenarios of biochar.

If you want to reduce mobility, here are a few things to keep in mind:

- Particle Size –larger particle may fractionate into smaller ones when hit by raindrops; but smaller particles will tend to leach and erode more quickly;

- Hydrophobicity – fresh char, especially made at low temps (<500) is likely to move more

- Soil texture matters as always! Sandy soils will experience more leaching & erosion.

What they didn’t say: A lot of chatter about biochar tends to tout ‘once & done’ benefits of biochar but in fact according to this chapter biochar can be quite mobile so ‘once & done’ could end up as ‘once & gone’ under the right (or really wrong) circumstances. Ancient soils such as Terra Preta in the Amazon or the Plagganthrepts soils in Europe (see picture in lower left hand corner above) are not the result of single applications. These soils were continually amended with char and other organic wastes for decades or centuries and created a deep dark soil profile that has persisted for millennia. It is highly unlikely that adding a single instance of biochar, even at high application rates, would create similar profiles. Thus adding lower rates more frequently may be preferable in the long run for both long-term carbon storage and soil fertility.