I’ve just returned from an amazing trip to Costa Rica where I met more people working with biochar than I know working with biochar in the entire state of New York (outside of researchers of course!). This shouldn’t really surprise me as Costa Rica is known as being very eco-centric (though some of the natives I met said that attitude doesn’t necessarily extend to agriculture) and they have been making biochar in one form or another for more than 20 years as I wrote about previously.

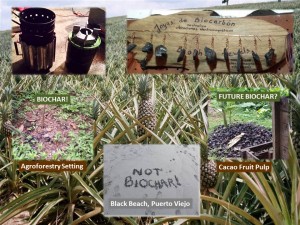

The Estufa Finca project has been hard at work providing grass roots education to rural farmers, immigrant laborers and others on how to make biochar using clean cook stoves (see picture). I was lucky enough to meet some of the folks they’ve trained and work with including an Agroforester that chars much of the debris from his permaculture forest and uses is around a wide variety of trees. He also makes biochar soap and toothpaste from it which of course I had to purchase to add to my collection (who knows, perhaps I’ll even try the toothpaste one of these days!). I also met an organic cacao/chocolate producer that converts forest and cacao debris into biochar and uses it around their ‘finca’. I didn’t find any ‘Charcolate’ there, but who knows, maybe someone has tried making this somewhere (anyone?)! I even found jewelry made from biochar (see ‘joyas de biocarbon’ pic) which was a first for me.

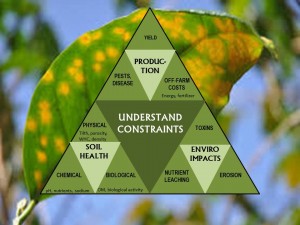

The sheer amount and diversity of underutilized biomass in the country is mindboggling. The other thing that boggles the mind is the craziness of the weather and its impact on soils and plant life. Visiting during wet season was perhaps a bit ‘deluge-ional’ in retrospect but it also opens your eyes to the vast amount of soil that washes down their streets, rivers and mountainsides with every heavy rain. [I swear they use snowplows to remove some of it since you would see a steep cut-off of soil all along sidewalks.] What really surprised me though is that for the first time in recent memory, Costa Rica has been suffering fairly substantial droughts during the dry season to such an extent that all water was shut off for 2 days at a time in one part of the country. Such is the face of climate change in the tropics.

With all that soil eroding goes an awful lot of chemicals. I learned that per hectare of crop land Costa Rica uses more pesticides than any other country on earth (can I get a ‘yikes’?)! We even had a crop duster fly over our car and dump its load of god knows what right over our heads. I held my breath, rolled up the windows and then laughed at my own naiveté. As if that would help!

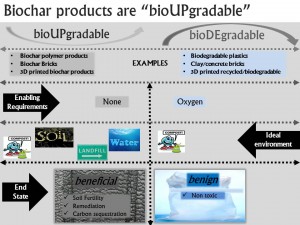

Not surprisingly, this scenario seems to me to be a prime opportunity for biochar. All that vegetation converted into biochar could help reverse the impacts of soil erosion and adsorb some of the pesticides to prevent them from contaminating ground water. If and when biochar is accepted as an official carbon offset product, it could also provide substantial help to Costa Rica in achieving their 2021 target of becoming the first carbon neutral country in the world!