Around this time of year my daughter’s school hosts a great event to teach kids about the old & new ways of tapping maple sugar trees to make maple syrup which includes lots of hands-on learning and tasting (YUM). Having attended in previous years as a chaperone, my interest was piqued especially when I saw that burning wood is an essential element of making maple syrup. This industry seemed ripe for a biochar intervention!

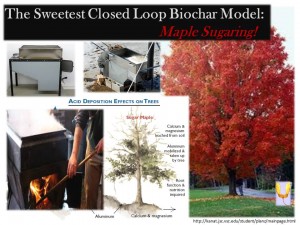

The mighty maple sugar tree, apart from adding gorgeous red color to the fall landscape and providing enormous natural capital as a keystone species in many New England and Mid-Atlantic forests, is one of the most highly regarded trees from an economic perspective. The wood is valuable for furniture and flooring while the syrup provides a natural sweetener first tapped by Native Americans. The maple syrup industry in the US is <$125M and provides seasonal work for thousands. Sadly the maple sugar tree is under attack from acid raid, drought, disease and climate change in general.

Evaporators are the key to the sap-to-syrup alchemy. Traditionally wood has been the fuel of choice for firing the evaporators. Inefficient evaporators can use up to 1 face cord of wood to make 1 gallon of maple syrup so some producers are moving towards fossil fuel based evaporators.

Given that wood-fired evaporators aren’t all that different from some of the biochar kilns on the market, I think it’s time to tap into a biochar solution for the world of maple sugaring! A little tweaking here and there would allow for a carbon rich by-product (yes, I’m talking about biochar!) from the evaporation process. Biochar could be added to the soil around the maple trees to counteract acidification, help maple trees to manage drought better and through improving soil microbial activity, improve their ability to stave off certain diseases.

To add one more closed loop to the whole maple sugaring with biochar design, a recent CHARquaintance told me that he adds a little bit of char to his maple syrup for a double dip of goodness! What a delicious & nutritious idea!

What other evaporators used in the food processing industry could we convert to ‘char-vaporators’ and build more closed loop or cascading biochar designs? Food for thought….