Recently I’ve seen a few articles that seem to be blurring the lines between biochar and torrefied wood, also called ‘bio-coal’. These two products can pass for identical twins to the average consumer, but really they are only fraternal twins (like me!).

Why so? Well basically certain physical and chemical properties are different due to differences in the production process. Bio-coal is produced at lower temps (i.e. 200 – 300C) as compared to higher ones for biochar (i.e. 400 – 800C). At temperatures below 270C the effect is basically to dewater the material which is really the main goal for torrefaction since the end use for this product is generally as renewable fuel. Of late there seems to be more talk of using it as a replacement for coal in electricity generation if the economics can work out (seems to be selling for <=$200/ton from what Master Google tells me).

[Allow me to jump on my soapbox for a moment here.]

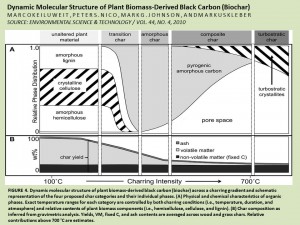

Temperature has a huge impact on recalcitrance (resistance to decomposition), pore size, surface area, pH, nutrient content, volatiles, carbon content and more which are all important if you are using the char in the soil. Have a look at the figure below which shows this in more detail. If consumers are looking for improved crop yield (not the only reason by a long shot…more on that in future posts) using biochar, then it is important to ‘know what you sow’ from a biochar perspective.

Renewable energy may be created during the biochar production process – some systems allow for the heat to be utilized and others do not. But biochar should not be considered as a renewable fuel! One of the primary end goals of biochar is to impede some portion of the carbon captured during a plant’s lifetime from returning to the atmosphere. Burning biomass to ash doesn’t accomplish that goal though it is still a huge improvement over burning coal or any other fossil fuels.

[Jumping off soapbox now…]