Recently I met with my State Senator to discuss a proposed incineration plant for a beautiful part of the Finger Lakes; the home of the white deer, the former Seneca Army Depot. My goal for the meeting was to provide input on a much more sustainable waste management technology: pyrolysis. In preparation for the meeting, I read up on the differences between incineration and pyrolysis. Though they both involve incomplete combustion, one is viewed as a pariah while the other a pioneer.

The reason that incineration is getting any play at all these days, after nearly two decades of very few new incineration plants in the U.S., is likely due to State legislation that will soon ban large scale organics to landfill. It’s also aided by the fact that more and more landfills are reaching capacity and neighbors are not keen to extend them or approve new ones due to toxic leaching and most notably persistent noxious odors emanating from the rising mountains of garbage. Incineration is also able to generate energy, though not in a net positive way. Claims that incineration is a renewable source of energy is more than a little disingenuous.

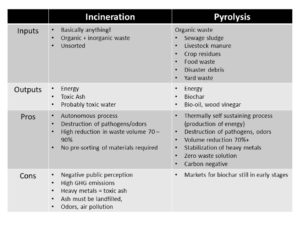

Serendipitously I found that researchers in London, Ontario, Canada have already compared incineration versus carbonization specifically for managing sewage sludge. They looked at fast and slow pyrolysis and looked at the leaching potential of chars generated from each type of pyrolysis (spoiler alert: slow p chars leach less). They concluded that pyrolysis is likely to be both economically and environmentally better than incineration. [Inserted chart incorporates some of their pros/cons but I’ve added to this.]

Compared to toxic ash that is generated from an incinerator where metals are mobile and may end up in landfill leachate, to a great extent pyrolysis immobilizes metals into the pore structure of the char. Given the metals content and the lack of consistency of the feedstock, this char may not find a ready market for amending soils, especially soils used to grow food or graze animals. But increasingly research is showing that various types of chars can be used for non-soil uses (e.g. composites, filtration, batteries, adsorbant for leachate etc.). The economics for pyrolysis over incineration will likely get better once large-scale markets for this type of biochar are developed.

Beyond the economics and environmental impacts though is the social impact. Those proposing incineration plants soon find themselves as social pariahs. Town hall meetings bring out droves of residents who are angry or afraid as their daily lives will be negatively impacted, not to mention the harm to soils, crops, and in my neck of the woods, tourism. Yes, they will likely find people willing to work in the plant as the area has few big employers, but its hard to imagine those working there will be bragging about it.

Now imagine a pyrolysis plant focused on producing clean, renewable energy and biochar instead of an incinerator. It will not be able to process all of the inorganic or toxic materials that an incinerator plant can, so volumes may not be as high. But there is plenty of organic waste in the form of sludge, manures, tree waste – especially after disasters like Sandy and winter storms, spoiled cardboard, old pallets and food waste to keep a pyrolysis plant charring away. Heat or electricity can be generated and instead continuing the legacy of a linear economy, a closed loop biorefinery could be born. Ancillary businesses that convert the biochar into different products such as building materials could be created.

More and more academic institutions in New York are starting to work with pyrolysis and biochar. Cornell has been at it the longest and has a world-class reputation for biochar used as a soil amendment. RIT has been exploring pyrolysis as an alternative for food waste management and I’ve been working with various teams of engineers at RIT and the University of Rochester testing biochar based building materials and composites. There is always much excitement from young engineers when they first learn about biochar. It’s something they like to be associated with and many continue to help educate others about it once they go off to their first jobs, some locally but many abroad. The choice between being a pariah, perpetuating an old and dirty technology or investing in a pioneering, regenerative XXI century bio-economy that other regions will want to emulate, should be a no-brainer. In the last few months I’ve been part of an increasing number of conversations within NYS, around the country and around the world where individuals and companies want to create this type of concept. It would be fantastic if the Finger Lakes could be on the leading edge of carbonizing organics.