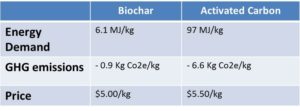

One of the most compelling above-ground markets for biochar is as a substitute for activated carbon. Activated carbon is used in a wide variety of applications from filtration to remediation. Problem is AC comes with a heavy carbon footprint and it’s not cheap. A recently published meta-analysis compares the energy demand, the GHG emissions and the economic performance of AC versus biochar used to filter certain heavy metals.

The authors compared LCA data from a variety of different ACs against 28 different types of biochars. The amount of energy required to make the various ACs ranged from 44 – 170 Mj/kg whereas the biochars required significantly lower amounts ranging from 1.1 – 16 Mj/kg. That shows that biochar needs 90% less energy to be produced! Somewhat surprisingly the chars at the lower end of energy requirements include chars made from digestate (1.1), paper sludge (1.1), and whisky draff (1.1) – which are all relatively high in moisture content.

On the GHG front the news in even more promising. Whereas AC production is responsible for 1.2 – 11 kg CO2 eq/kg, all of the biochars analyzed had net negative emissions from -.1 to -3.5 with miscanthus char showing the most sequestration potential.

Comparing economic performance must take into account both price and adsorption capacity. I have a disagreement with the authors on the pricing data used for comparison purposes. While efforts were made to contact multiple vendors to get an average price, the price used in the study for biochar is US$5/kg (i.e. $2.27/lb or $4,545 per short ton). Although these prices might represent retail prices for small quantities of biochar, no one that I know in the biochar world is selling char for >$4,500 per ton! In fact as more and more production capacity is coming on line, the price is coming down rather substantially. Depending on the type of biochar and the demand for that particular char, current prices seem to range from $500 – $2,000 per ton (i.e. .55 – $2.20 per kilo).

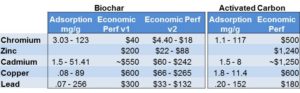

The authors include an excellent table which provides comparisons of the adsorptive capacity of different ACs and biochars for 4 different metals: Chromium, Cadmium, Copper and Lead. Using this data and a normalized price for biochar, an economic performance comparison is provided. The ranges for adsorption capacity are provided below combined with the economic performance as stated by the authors (v1) and a revised version based on more realistic biochar pricing as stated by yours truly (v2).

What is most interesting to me is a comparison of the best biochar against the best AC. For each metal there was at least one biochar that had higher adsorption capacity mg/g than the best AC. Not only that but some of the biochars that out-performed AC had significantly lower surface areas (e.g. dairy manure biochar, the best performing biochar for cadmium filtration has a surface area pf 5.61 m2/g vs the best performing AC which had a surface area of 984). This indicates that something other than surface area is responsible for the high rates of cadmium removal (51 mg/g for dairy manure biochar vs 8 mg/g for AC).

When more realistic prices for biochar are taken into consideration, the economic performance of biochar versus AC for heavy metals removal becomes even more favorable. The take-aways from this and a growing number of peer reviewed studies on the use of biochar to filter both toxins and nutrients are that 1) significantly less energy is needed to produce biochar based adsorbents; 2) the GHG emissions related to production for biochar are all negative as compared to all positive emissions for AC; and 3) biochar is significantly cheaper than AC for metals removal. That should be a pretty compelling value proposition. The key will be, as with all things biochar related, to select the right biochar for the job. This study shows that what you are removing may require a different kind of biochar, but perhaps the ultimate solution will be a blend of different biochars.