Listening to a webinar on Agriculture & Climate Change Adaptation hosted by the New York State Department of Environmental Conservation, I was at once enlightened and yet disheartened. Sadly biochar received nary a mention. To fill the void, allow me to present my perspective on how biochar can help not only with climate change adaptation but also with climate mitigation.

Climate Mitigation

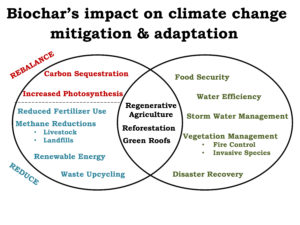

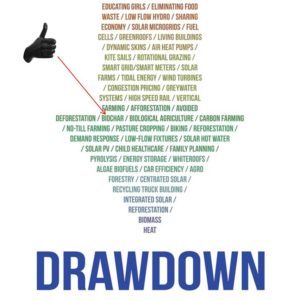

Mitigation comes in two basic flavors: reducing and rebalancing. The vast majority of interest and investment seems to focus on reducing; i.e. lowering current emissions of various greenhouse gases (GHGs). There are many, many ways to do this but using less energy and/or using cleaner energy (e.g. solar, wind, geothermal, hydro, etc.) are amongst the most common recommendations. Reducing is absolutely critical to mitigating the worst forecasts, but it is far from sufficient. Rebalancing is perhaps even more important. Rebalancing means shifting excess atmospheric CO2 back from whence it came: terra firma (I will leave the discussion on ocean sequestration and release to others).

Biochar can help on the reduction side in a variety of ways. Renewable energy in the form of heat, which can be converted into electricity, is created during the production of biochar. Sometimes a portion of this heat is used for drying feedstock prior to carbonization, but the vast majority of it is available to displace fossil fuel derived energy.

Further on the reduction side, we can look to fertilizer use, especially Nitrogen (N), which comes with a particularly heavy carbon footprint both on the energy-intensive production side, but even more so on the application front. Excessive N use is rampant around the world as farmers desperately try to maximize annual yield in soils long since exhausted of inherent nutrients. Microbes convert nitrogen into nitrous oxide (N2O) which is 300x more devastating to the climate than CO2. Biochar blended with either organic nutrients (e.g. manure, urine, compost) or with synthetic fertilizer can reduce the amount of fertilizer needed as it provides a bonding structure for the nutrients that slowly releases them and prevents unwanted leaching into groundwater or as GHG into the atmosphere.

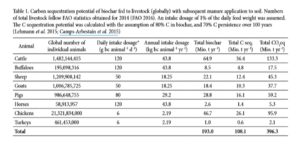

Biochar can also reduce methane (CH4) emissions from at least two significant sources: bovines and rubbish. The world’s 1.5 billion cows as well as other livestock belch out an alarming amount of CH4, a GHG 25 to 80 times more potent than CO2. In the US, livestock is the 2nd highest source of CH4 emissions after Natural Gas. Research has shown that adding biochar to livestock feed can materially reduce enteric methane emissions as well as provide other health benefits to animals. It can also serve as a low cost delivery mechanism for getting biochar into soils (via manure). Similarly research has shown that biochar used at landfills, either as daily cover or as part of a capping material when landfills are retired, can also reduce CH4 emissions.

Biochar can also reduce significantly emissions by diverting organic materials from going to landfills, which represent the 3rd largest source of CH4 emissions in the US. Carbonization minimizes biomass volume by 75 – 90% depending on the production parameters. In the right circumstances, this can reduce transportation tremendously and it can also prevent CH4 from being generated at landfills in the first place.

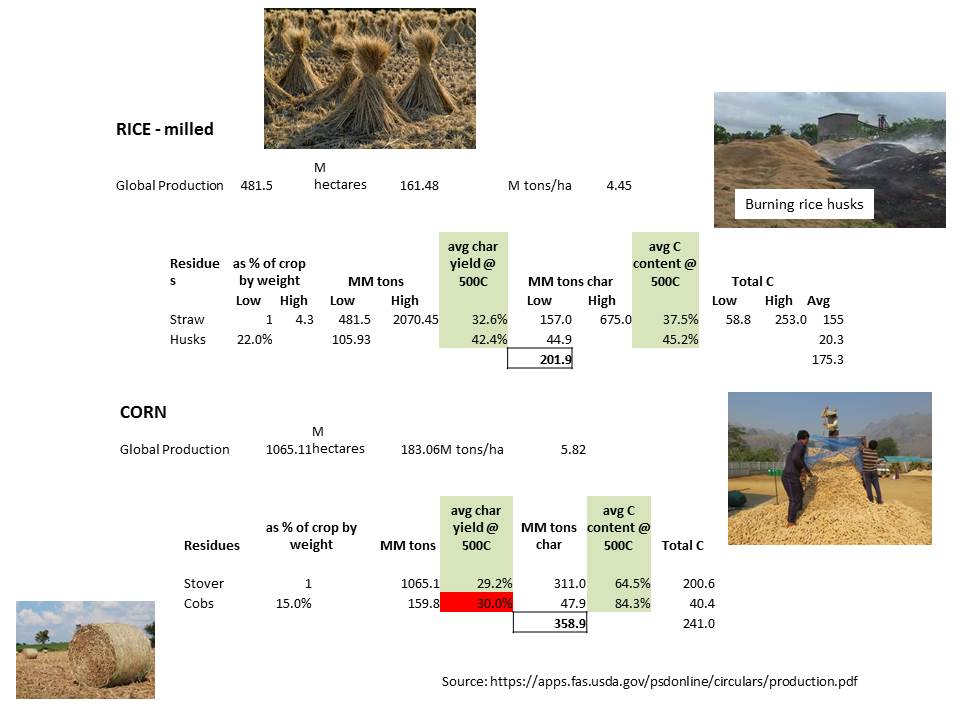

On the rebalancing front, biochar can help mitigate climate change in two critical ways: by boosting photosynthesis and by interrupting or massively slowing down the normal carbon cycle. Using biochar to plant trees or crops has shown that plant survival and growth are improved which can boost overall photosynthetic activity. The CO2 absorbed by plants is stored until they die and then it normally decomposes back into CO2 and re-enters the carbon cycle. However, if the trees or plants are converted into long lived products (e.g. furniture) or carbonized into biochar, the natural carbon cycle is interrupted. When biomass is carbonized, up to 50% of the carbon absorbed during the tree or plants lifetime is converted into stable carbon and if the resulting biochar is put in the soil or embedded in other long-lived products (e.g. building materials), it will not return to the atmosphere for many centuries. This is an example of what is commonly referred to as carbon sequestration.

Adaptation

Adaptation focuses on strategies that can be employed to deal with the impacts currently being experienced as a result of climate change. A growing number of adaptation strategies are being employed from relocation of populations impacted by rising seas, to changes in planting schedules and/or crop types, to improved drainage or more successful integrated pest management. As with mitigation, biochar can help adapt to the impacts of climate change in a variety of ways, a sampling of which are provided here.

Climate change is wreaking havoc on global food security. Droughts, floods and storms are both more common and more fierce. Increased heat, disease and land degradation are amongst the other threats to food security, compliments of climate change. Biochar can help improve crop yields, plant resistance to pests and pathogens and retain water longer in areas prone to droughts, all of which will help to build more resilient food production systems. Biochar also helps reduce the amount of water needed for irrigation which, in an increasingly water constrained world, is critical. Some research is showing that it can help to recharge and filter ground water supplies which can lead to healthier crops and improved human health.

Storm water management is becoming enormously crucial especially in flood-prone areas. Biochar is being successfully used as a strategy to manage urban stormwater from Seattle to Stockholm, but can also be used by farmers in drainage ditches or potentially in lieu of expensive tiles, and by gardeners and home owners in rain gardens.

Fierce and frequent fires such as those swallowing up Southern California at the moment threaten lives and landscapes. Drought is turning trees to tinder and invasive species bring unwanted biomass which also increases the risk of wildfires. Biochar made from beetle-kill pines is underway in places like Colorado and teams of volunteers in Oregon have been thinning vast amounts of brush to reduce fuel loads (more info here).

Communities that have suffered devastating impacts of hurricanes or monsoons could, as I’ve noted before, greatly benefit from biochar in many ways. From dealing with debris to generating desperately needed power to remediating toxified soils and replanting ravaged perennials, biochar can help rebuild and regenerate.

Some biochar scenarios straddle both mitigation and adaptation. These include its use in regenerative agriculture which focuses on building soil fertility and increasing biodiversity; reforestation or afforestation; and urban agricultural practices such as green roofs and tree establishment.

This is far from an exhaustive accounting of biochar’s benefits when it comes to climate change mitigation and adaptation but it should provide the reader with an overview of biochar’s unmatched usefulness and versatility.